246 results for the term ‘Activities’

Aleena Madathiparambil Saju - student at the University of Sheffield

"I’ve been to many cities around England and at the end of the day I’m always glad that I chose to study at Sheffield."

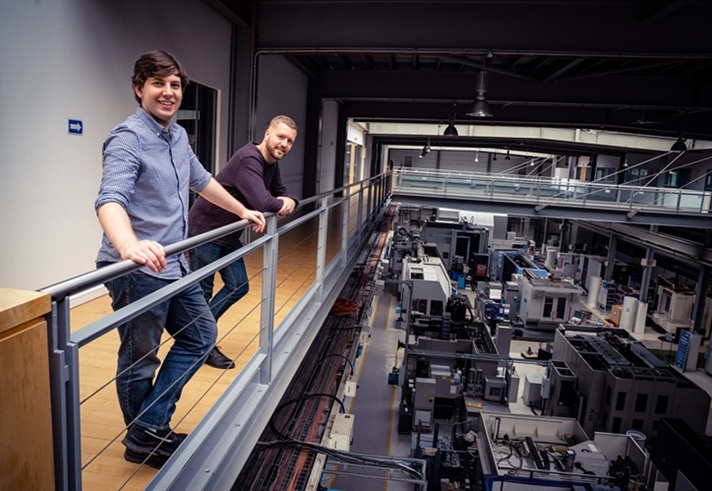

Nuclear AMRC to support next phase of Rolls-Royce SMR development

The Nuclear AMRC will work with Rolls-Royce on the next phase of its small modular reactor (SMR) development programme, for which the government has confirmed £210 million of funding.

Making manufacturing fit for the future

FourJaw has secured grant funding to accelerate the development of what has been dubbed the ‘fit bit for UK manufacturing.’

ITM Power: Splitting water to power machines

ITM Power partnered with The University of Sheffield – world renowned for its expertise in energy innovation – to plan and fund a National Hydrogen Research Innovation and Skills Centre. It’s here they’ll research the safe and efficient manufacturing of hydrogen using low or zero carbon sources of energy.

How Excel Martial Arts saves £5,000 yearly with Business Sheffield’s Low Carbon Grant

At Business Sheffield, we’re committed to helping local organisations become more efficient, sustainable and resilient. Through our Low Carbon Grant, we support Sheffield businesses to lower their energy use, reduce running costs and reinvest their savings where it matters most.

Summer events

Summer 2025 is looking like a busy one for Sheffield, with major music festivals, sporting events, vibrant outdoor markets and family entertainment.

Leaf and Shoot

A former builder who dreamed of the good life has transformed the forgotten underground vaults of Kelham Island into a haven for producing organic edible produce after calling on help from Launchpad, a unique programme which provides business support to new and aspiring entrepreneurs based in the Sheffield City Region.

Skateboarding in Sheffield

Skateboarding has a long, rich history in Sheffield. The city boasts an impressive roll call of pro and skate industry sponsored skaters, and punches above its weight on the UK scene with a solid skateboarding community.

Rachel Fletcher, growth advisor

Meet Rachel from our team of business advisors. Known for her supportive, practical, and pragmatic advice, Rachel was very involved in supporting companies during the pandemic to help them identify and access the correct grants and send through the required information.

World’s first net zero transatlantic flight to fly from London in 2023

The first ever net zero transatlantic flight will take off from the UK next year as part of a pioneering research project to fly across the pond using solely sustainable aviation fuel.